Laminate layers are stack together using

- Two-component, non-solvent-based polyurethane adhesives for laminating transparent, printed and metallised plastic and aluminium foil to be used for food packaging. The application value of the adhesive mixture (resin) with a hardener ranges from 1.5 to 2.5 g/m2. As a result of reaction between the two components a polymer layer is created to combine the bases of plastic foil. Upon hardening the layer is transparent, odourless, flexible and wear-resistant. Two-component adhesives with greater resistance should be used for packaging with aggressive content.

- Single-component, non-solvent-based polyurethane adhesives that cross-link in the presence of humidity and at certain temperatures, which are good for laminating paper and cardboard with transparent plastic and/or metallised foil. Adhesive application value ranges from 2.8 to 4.0 g/m2.

- Solvent-based two-component adhesives (resin + hardener) + solvent (ethyl acetate) applied from rotogravure cylinders. Pressure rubber roller (sleeve) whose width corresponds to the width of the laminated substrate is necessary for laminating with solvent-based adhesives. Solvent-based adhesives are more flexible and ensure greater gloss. They are used mostly for combining such materials as:

Valmet Rotomec SL500 Laminator

- one- and two-component solvent-free polyurethane adhesives

- possible additional activation of foil through corona-treatment on the laminated side (adhesive application side)

- maximum roll diameter: 1000mm

- maximum roll weight: 1000kg

- maximum tape band width: 1200mm

- minimum tape band width with special equipment: 400mm

- unwinding from cores with diameters of: 76.2mm, 152mm

- winding core diameters; 76.2 mm, 152mm

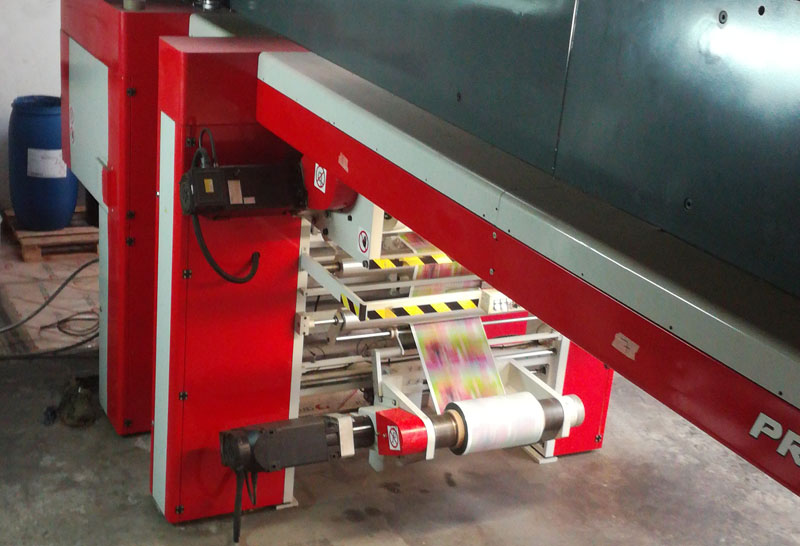

Svecom Princess 110 Laminator

- a two-system laminator: solvent free and solvent-based adhesives

- applying Cold seal adhesives in register

- applying solvent-based adhesives and/or varnishes, single-colour print from 60l/cm rotogravure raster cylinder; 70 l/cm

- corona-treatment on the laminated side (adhesive application side)

- aminated material band width: minimum 370mm, maximum 1150mm

- laminating (adhesive application) width: minimum 362 mm, maximum 1100mm

- unwinding/winding roll diameter: maximum 1000mm, max. roll weight 1100 kg

- unwinding/winding from/onto rolls with the diameters of 76.2mm; 152 mm

- maximum laminating speed: up to 450 m/min, depending on the laminate